Cold and Ultra Cold Vial Helium Leak Testing

THE CHALLENGE

A global pharmaceutical entity (Client B) approached Leak

Detection Associates (LDA, now a PTI company) with vials for

helium leak testing services. The vials were of the same size; however,

one was of glass composition and the other was a thermoplastic material.

Each contained the same neck finish to accommodate a press-fit integral crimp/stopper component. They

were interested to see how various temperature storage conditions might affect their helium leak rates. The

temperatures of interest were refrigerated (2 - 8°C), -40°C, -60°C, and -80°C.

THE SOLUTION

Client B provided LDA one hundred (100) 2R size

glass and plastic vials that were prepared by first

drilling a hole (3.2mm dia.) in the base of each

sample. After cleaning residual debris, the crimp/

stoppers were applied to the finish using a small

arbor press. The purpose of the hole was to supply

100% helium gas during the leak test cycle. This

procedure is known as the 100% Helium Flow or

Continuous Helium Flow method. This was a client

stipulated method since they did not want to

introduce potential leaks by puncturing the stoppers

to allow helium into the sealed vials. Each vial set

(25 samples) were allowed to condition at their test

temperature for 24 hours prior to helium leak testing.

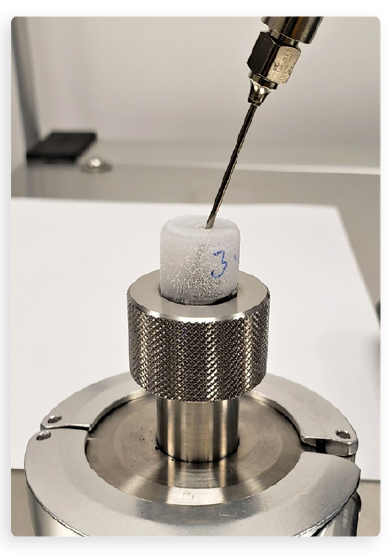

After the conditioning period, vial samples were individually

analyzed utilizing a SIMS helium leak detector machine.

Once removed from the cold environment, the sample was

immediately placed on the vacuum test fixture and the leak

test cycle was initiated. Approximately 20 seconds into the

leak test, a tube was inserted into the exposed hole in the

vial base and a flow of helium gas (25cc/min) continued for

10 seconds. The initial test cycle allowed for the leak rate to

stabilize prior to introducing the helium gas. Any increase in

the helium leak rate would indicate a leak pathway from the

crimp/stopper area since this was the only section of the vial

exposed to the helium leak detector. Once the full test cycle

was completed, the next vial sample was removed from cold

storage and the same test procedure was repeated until all

25 vials were completed. Subsequent leak tests of the other

cold storage conditions were carried out by first allowing the

24 hour conditioning period of the vial sets. Helium leak rate

data was collected from all four vial sets.

THE RESULT

After collecting and tabulating the helium leak rate data from each of the four temperature storage conditions,

it was of interest to note that all of the vial samples did not exhibit any helium leakage – all were in the low/mid

10-9 mbar-L/sec. This leak rate level is well below the Kirsch helium leak rate criteria (10-6 mbar-L/sec) ensuring

that these vials would most likely not encounter microbial or sterility problems during their intended shelf life.

This study confirmed to the client that their press-fit vial crimp system was extremely robust, even well beyond

the glass transition temperatures of most rubber stopper compounds.